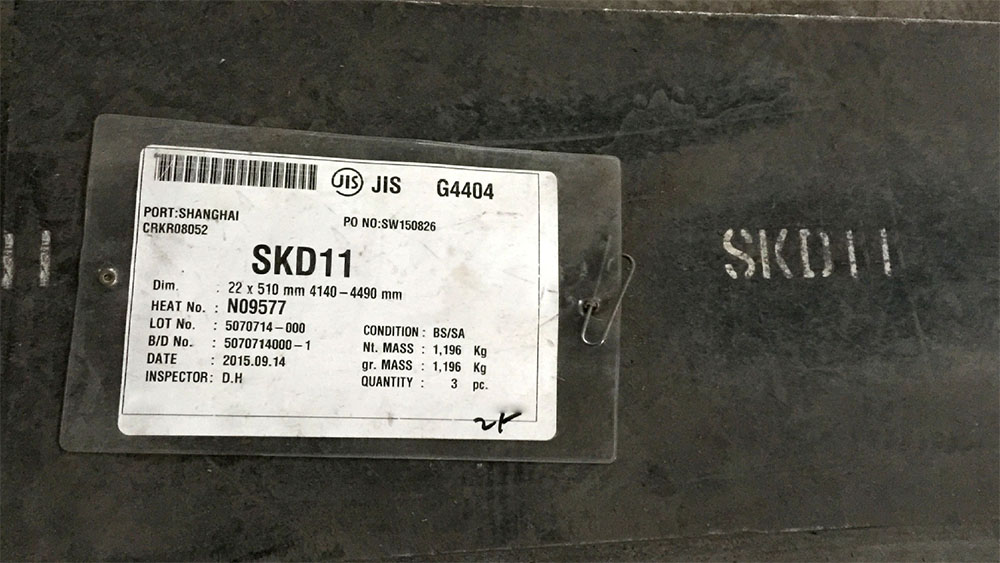

SKD10 and SKD11 Steel

Both SKD10 and SKD11 steel are high carbon and high chromium cold-work alloy tool steels with good hardenability, small heat treatment deformation, high hardness, high wear resistance and impact resistance.

Material Properties

The following table lists SKD10 and SKD11 material properties including chemical composition, physical and hardness, etc.

Chemical Composition

SKD10 and SKD11 steel chemical composition is listed in the following table.

| Chemical Composition, % | |||||||||

| Standard | Steel | C | Si | Mn | P, ≤ | S, ≤ | Cr | Mo | V |

| JIS G4404 | SKD11 | 1.40-1.60 | ≤0.40 | ≤0.60 | 0.030 | 0.030 | 11.00-13.00 | 0.80-1.20 | 0.20-0.50 |

| JIS G4404 | SKD10 | 1.45-1.60 | 0.10-0.60 | 0.20-0.60 | 0.030 | 0.030 | 11.00-13.00 | 0.70-1.00 | 0.70-1.00 |

| ASTM A681 | D2 | 1.40-1.60 | 0.10-0.60 | 0.10-0.60 | 0.030 | 0.030 | 11.00-13.00 | 0.70-1.20 | 0.50-1.10 |

Physical Properties

SKD11 material physical properties are listed in the table below including density, melting point, specific heat, elastic modulus (modulus of elasticity), and coefficient of thermal expansion (CTE).

Notes:

- 10-6·K-1 = 10-6/K

- 1 Ω·mm²/m = 1 μΩ·m

- 1 g/cm3 = 1 kg/dm3 = 1000 kg/m3

- 1 GPa = 1 kN/mm2

- 1 MPa = 1 N/mm2

| SKD11 Physical Properties | |

| Density, g/cm3 (lb/in3) | 7.80 (0.282) |

| Melting point, °C (°F) | 1420 (2590) |

| Elastic modulus (Modulus of Elasticity), GPa (106 psi) | 207 (30) |

| Thermal conductivity, W/m·K (Btu/ft · h ·°F) | 26.1 (15.09) |

| Coefficient of thermal expansion (CTE), μm/m·K | 12.0 |

SKD10 and SKD11 Heat Treatment

Annealing

SKD10 and SKD11 tool steel annealing temperature: 830 to 880 °C (1526-1616 °F), slow cooling, annealed hardness: ≤255 HB.

Hardening and Tempering

- SKD10 – Quenching temperature: 1020±10 °C air cooling; Tempering temperature: 180±10 °C air cooling; quenched and tempered hardness: 720 HV.

- SKD11 – Quenching temperature: 1030±10 °C air cooling; Tempering temperature: 180±10 °C air cooling; quenched and tempered hardness: 653 HV.

Applications

Typical applications include

- Blanking die

- Polishing tools

- Casting mold

- Drawing mould

- Drawing die

- Forming mold

- Crimping die

- Hot forging die

- Laminated mold

- Thread rolling die

- Trimming mold

- Cold extrusion die

- Measuring tool

- Lathe Center

- Punch

- Forming and bending rolls

- Spinning tools

- Knurled

- Slitting knife

- Broach

- Wear plate

- Mandrel

- Knives

- Shear blades, etc.

SKD10 & SKD11 Material Equivalent

SKD10 & SKD11 tool steel equivalent to US ASTM, European EN (Germany DIN, British BSI, French NF…), ISO, and Chinese GB standard (For reference).

| SKD10 & SKD11 Equivalent Material | |||||||||||||||||

| Japan | US | European | ISO | China | Australia | India | Rusia | Korea | |||||||||

| Standard | Steel | Standard | AISI (UNS) | Standard | Steel Number (Steel Name) | Standard | Steel Number (Steel Name) | Standard | Name | Standard | Grade | Standard | Grade | Standard | Grade | Standard | Grade |

| JIS G4404 | SKD10, SKD11 | AISI, ASTM A681 | D2 (T30402) | EN ISO 4957 | 1.2379 (X153CrMoV12) | ISO 4957 | 1.2379 (X153CrMoV12) | GB/T 1299 | Cr12Mo1V1 | ||||||||

Note: The chemical composition of SKD10 is closer to D2, 1.2379 and Cr12Mo1V1 than SKD11 steel, SKD11 was added to this table because it is much more commonly used than SKD10 in Japan.