Galvanized Welded Wire Mesh Panels, Sheets & Rolls for Fence

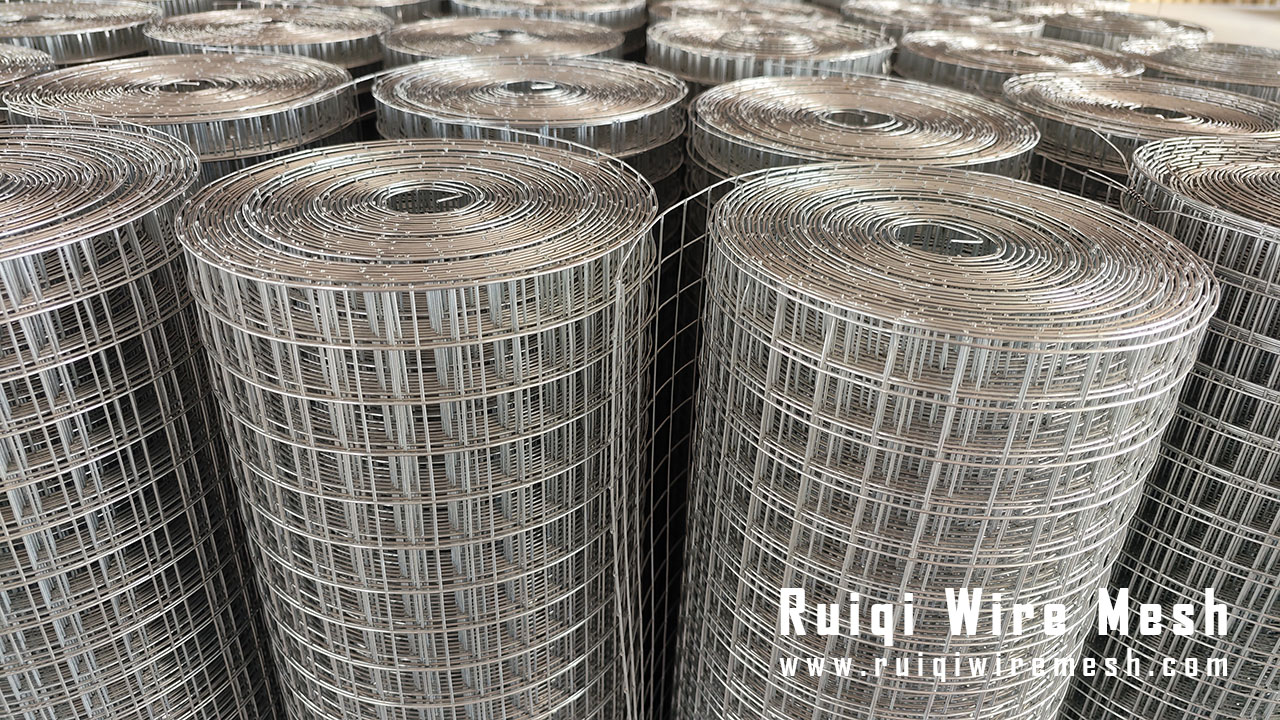

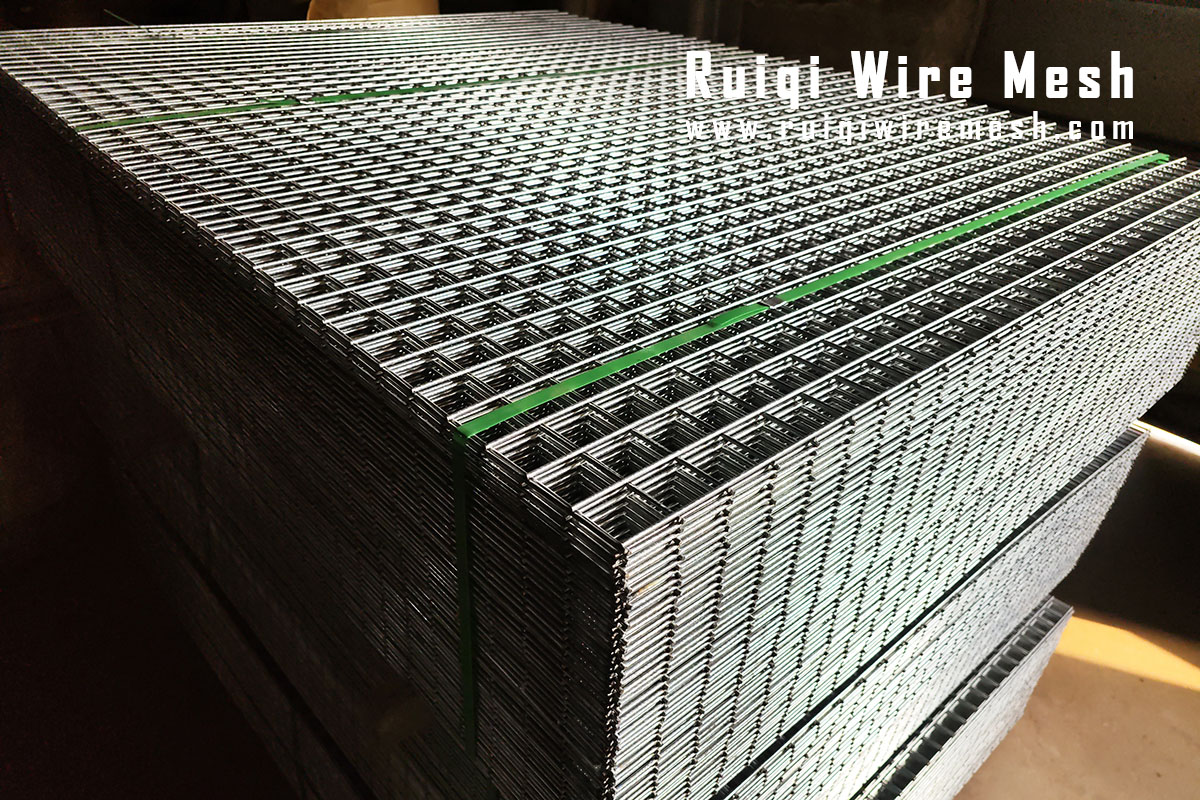

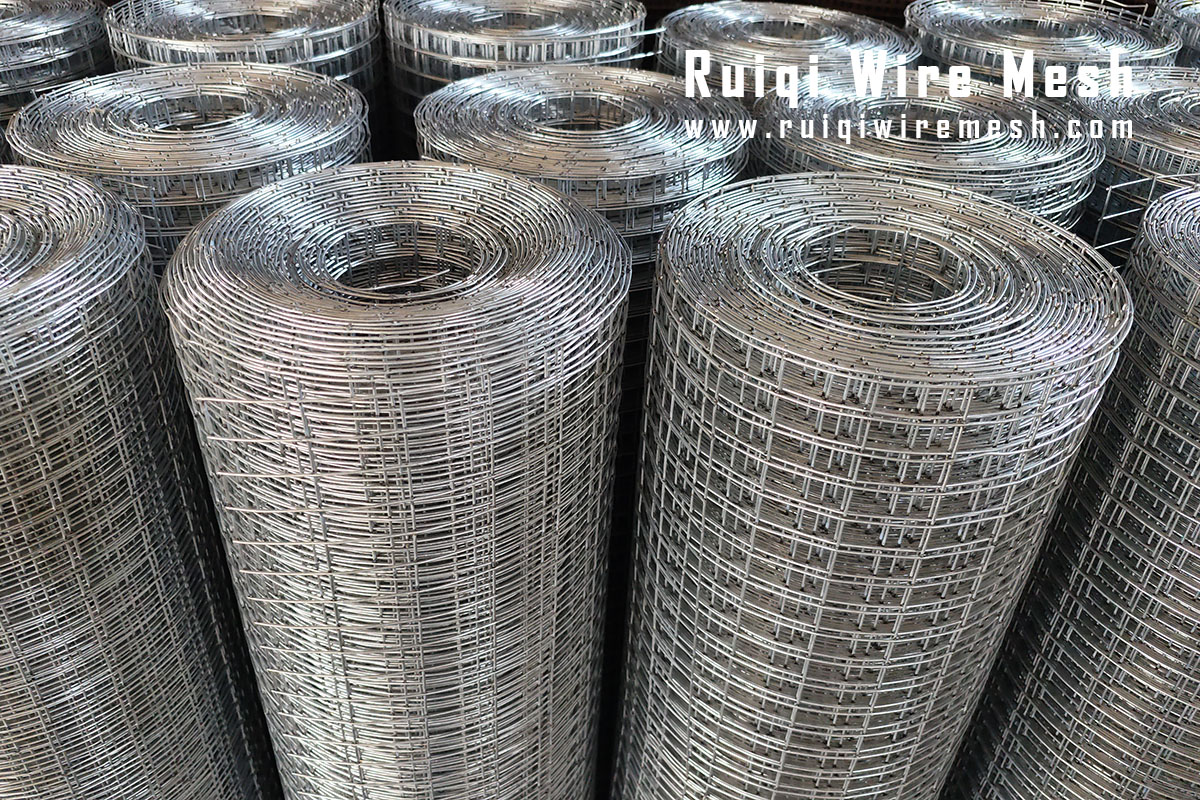

Galvanized welded wire mesh panels or sheets are made by welding pre-galvanised steel wire by an electric welding machine, or welding plain steel wire into mesh and then galvanizing as a whole. Galvanized welded wire mesh rolls are versatile metal products widely used in industrial and commercial fields, building construction, roads and public facilities, farm fence, etc.

Galvanizing, a surface treatment process to prevent rust, is a relatively inexpensive surface protection method that can be done before or after wire mesh fabrication. Stainless steel weld mesh itself has excellent rust resistance, so no additional surface treatment is required, and the surface can remain bright for a long time even in a humid environment that is not contaminated. The galvanized weld mesh sheets or panels will lose its surface brightness after a period of use, and once the galvanised layer is damaged, it will lose its surface protection and begin to rust.

Types of Galvanized Welded Wire Mesh Rolls & Panels

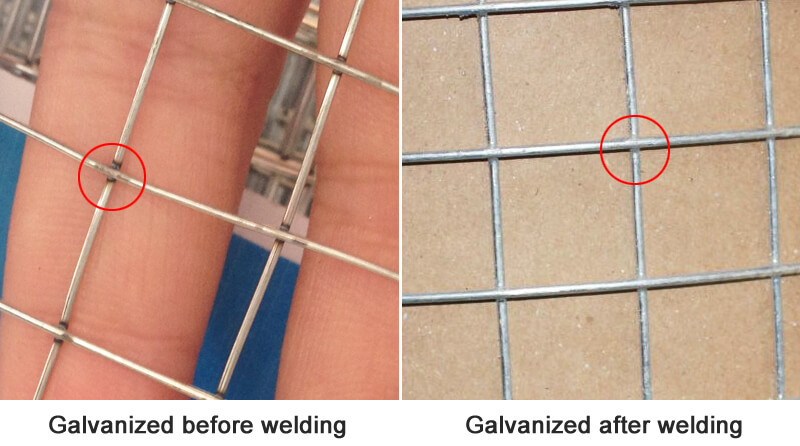

There are two processing methods of galvanized welded wire mesh panels, one is galvanised before welding, and the other is galvanised after welding.

Galvanized before welding means that the wire used to make the wire mesh itself has been galvanized before the wire mesh is welded. The advantage of this manufacturing method is that it is cheaper; The disadvantage is that the zinc layer is destroyed by welding the intersection of each horizontal and vertical wire, thereby reducing the overall corrosion resistance (Rust begins at the intersection, and over time, the welding joints crack due to corrosion).

Galvanized after welding refers to welding the ungalvanized steel wire into a wire mesh first, and then putting it into a molten zinc bath to galvanize it as a whole. The advantage of this method is that the entire surface of the wire mesh, including the welding joints at the intersection, is covered with zinc layer, so the overall corrosion resistance is better. The disadvantage is that the price is more expensive than the former.

Specifications of Galvanized Weld Mesh Panels, Rolls & Sheets

| Specifications of galvanized welded wire mesh hardware cloth | |||||

|---|---|---|---|---|---|

| Mesh | Diameter | Weight (Approximate) | |||

| mm | in. | mm | in. | kg/m2 | lb/100 ft2 |

| 6.4 | 1/4 | 0.55 | 0.0217 | 1.66 | 34 |

| 8.5 | 1/3 | 0.81 | 0.0317 | 0.65 | 13 |

| 10.6 | 3/7 | 0.90 | 0.0354 | 1.21 | 25 |

| 12.7 | 1/2 | 0.66 | 0.0258 | 1.86 | 38 |

| 12.7 | 1/2 | 0.81 | 0.0317 | 1.66 | 34 |

| 12.7 | 1/2 | 1.04 | 0.041 | 2.54 | 52 |

| 12.7 | 1/2 | 1.57 | 0.062 | 1.22 | 25 |

| 12.7 x 25.4 | 1/2 x 1 | 1.04 | 0.041 | 1.32 | 27 |

| 12.7 x 25.4 | 1/2 x 1 | 1.45 | 0.057 | 0.70 | 14 |

| 12.7 x 25.4 | 1/2 x 1 | 1.57 | 0.062 | 0.47 | 10 |

| 15.9 | 5/8 | 1.20 | 0.047 | 1.11 | 23 |

| 19.0 | 3/4 | 1.04 | 0.041 | 1.11 | 23 |

| 19.0 | 3/4 | 1.45 | 0.057 | 1.27 | 26 |

| 19.0 | 3/4 | 1.57 | 0.062 | 1.22 | 25 |

| 25.4 x 12.7 | 1 x 1/2 | 1.45 | 0.057 | 0.69 | 14 |

| 25.4 x 12.7 | 1 x 1/2 | 1.57 | 0.062 | 1.07 | 22 |

| Mesh Size | Wire Gauge (BWG) | |

| Inch | mm | |

| 1/4″ x 1/4″ | 6.4mm x 6.4mm | 22, 23, 24 |

| 3/8″ x 3/8″ | 10.6mm x 10.6mm | 19, 20, 21, 22 |

| 1/2″ x 1/2″ | 12.7mm x 12.7mm | 16, 17, 18, 19, 20, 21, 22, 23 |

| 5/8″ x 5/8″ | 16mm x 16mm | 18, 19, 20, 21 |

| 3/4″ x 3/4″ | 19.1mm x 19.1mm | 16, 17, 18, 19, 20, 21 |

| 1″ x 1/2″ | 25.4mm x 12.7mm | 16, 17, 18, 19, 20, 21 |

| 1-1/2″ x 1-1/2″ | 38mm x 38mm | 14, 15, 16, 17, 18, 19 |

| 1″ x 2″ | 25.4mm x 50.8mm | 14, 15, 16 |

| 2″ x 2″ | 50.8mm x 50.8mm | 12, 13, 14 |

Other specifications can be customized according to customer requirements.

Applications

Typical uses of galvanized weld wire mesh panels, sheets or rolls include enclosures, farm fence, garden fence, poultry fence & cage, aviary mesh, handrail infill panels, safety guards, construction concrete reinforcement mesh, plaster mesh, etc.