European Standard Designation Systems for Steel Names

1. Designation & Meaning of Structural Steel Names

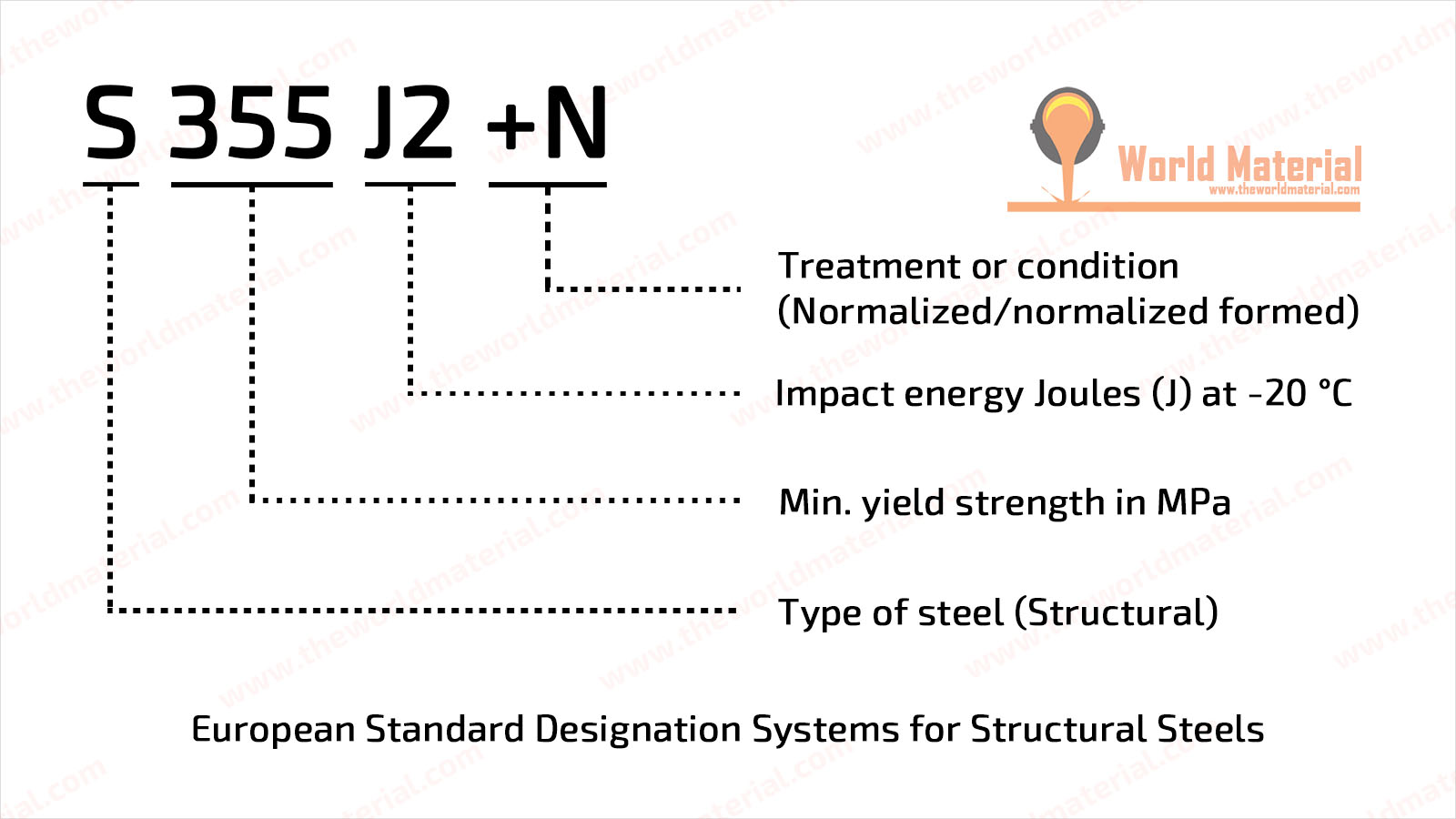

- The first letter indicates the type of steel,

- The following digits indicates the yield strength MPa;

- The 2 symbols immediately after the yield strength value indicate the quality grade of the steel;

- The symbols immediately after the quality grade indicate characteristic/uses or treatment, and

- finally a plus sign (+) and a symbol indicate delivery/treatment conditions, coatings or special requirements.

For example,

S235JRC+C Meaning:

- “S” is the abbreviation for Structural steel.

- “235” refers to the yield strength in MPa.

- J indicates Joules (27 J)

- R is the abbreviation for Room temperature (20 °C).

- C means special cold forming (cold flanging, cold roll forming or cold drawing).

- “+C” indicates cold work hardened.

S235JRC+C Meaning: Structural steel (S) with a specified minimum yield strength 235 MPa at room temperature, minimum impact energy 27 J at room temperature 20 °C (JR), suitable for cold flanging (C), delivery condition +C (cold work hardened).

S355J2W Meaning: Structural steel (S) with a specified yield strength ≥355 MPa at room temperature, impact energy ≥27 J at -20 °C (J2), and is weather resistant (W).

S355MC Meaning: Structural steel (S), thermomechanically rolled (M), with a specified minimum yield strength at room temperature of 355 MPa (355) and suitable for cold forming (C).

| Basic constituent symbols indicating the quality grades of structural steel | |

|---|---|

| Symbol/Number | Meaning |

| S | Structural steel |

| 235 | Yield strength: 235 MPa |

| JR | Joules (27J) at Room temperature (+20°C) |

| J0 | Joules (27J) at 0°C |

| J2 | Joules (27J) at -20 °C |

| J3 | Joules (27J) at -30 °C |

| J4 | Joules (27J) at -40 °C |

| J5 | Joules (27J) at -50 °C |

| J6 | Joules (27J) at -60 °C |

| KR | Joules (40J) at Room temperature (+20°C) |

| K0 | Joules (40J) at 0°C |

| K2 | Joules (40J) at -20 °C |

| K3 | Joules (40J) at -30 °C |

| K4 | Joules (40J) at -40 °C |

| K5 | Joules (40J) at -50 °C |

| K6 | Joules (40J) at -60 °C |

| LR | Joules (60J) at Room temperature (+20°C) |

| L0 | Joules (60J) at 0°C |

| L2 | Joules (60J) at -20 °C |

| L3 | Joules (60J) at -30 °C |

| L4 | Joules (60J) at -40 °C |

| L5 | Joules (60J) at -50 °C |

| L6 | Joules (60J) at -60 °C |

| A | Precipitation hardening |

| M | Thermomechanically rolled |

| N | Normalized or normalized rolled |

| Q | Quenched and tempered |

| C | Special cold forming (cold flanging, cold roll forming or cold drawing) |

| D | Hot dip coating |

| E | Enamelling |

| F | Forgings |

| H | Hollow section |

| L | Low temperature |

| P | Sheet piling |

| P | For the class with a greater phosphorus content (only in the case of grade S355) |

| S | Ship building |

| T | Tubes |

| W | Weather resistant (improved atmospheric corrosion resistance) |

| Symbols that indicate the treatment of steel products | |

|---|---|

| Symbol | Meaning |

| +A | Soft annealed |

| +AC | annealed to achieve spheroidized carbides |

| +AR | as rolled (without any special rolling and/or heat treatment conditions) |

| +AT | solution annealed |

| +C | cold work hardened |

| +Cxxx | cold work hardened with a minimum tensile strength of xxx MPa |

| +CPxxx | cold work hardened with a minimum 0,2 % proof strength of xxx MPa |

| +CR | cold rolled |

| +DC | delivery condition at manufacturer’s discretion |

| +FP | treated to ferritic-pearlite structure and hardness range |

| +HC | hot rolled followed by cold hardening |

| +I | isothermically treated |

| +LC | skin passed (temper rolled or cold drawn) |

| +M | thermomechanically formed |

| +N | normalized or normalized formed |

| +NT | normalized and tempered |

| +P | precipitation hardened |

| +Q | quenched |

| +QA | air quenched |

| +QO | oil quenched |

| +QT | quenched and tempered |

| +QW | water quenched |

| +RA | recrystallization annealed |

| +S | treated for cold shearing |

| +SR | stress relieved |

| +T | tempered |

| +TH | treatment to hardness range |

| +U | untreated |

| +WW | warm worked |

| Symbols for steel products indicating the type of coating | |

|---|---|

| Symbol | Meaning |

| +A | hot dip aluminum coating |

| +AS | aluminum silicon alloy coating |

| +AZ | aluminum zinc alloy (>50 % Al) coating |

| +CE | electrolytic chromium/chromium oxide coating (ECCS) |

| +CU | copper coating |

| +IC | inorganic coating |

| +OC | organic coating |

| +S | hot dip tin coating |

| +SE | electrolytic tin coating |

| +T | hot dip lead tin alloy (terne) coating |

| +TE | electrolytic lead tin alloy (terne) coating |

| +Z | hot dip zinc (galvanized) coating |

| +ZA | hot dip zinc aluminum (>50 % Zn) coating |

| +ZE | electrolytic zinc coating |

| +ZF | hot dip zinc iron (galvannealed) coating |

| +ZM | hot dip zinc magnesium coating |

| +ZN | electrolytic zinc nickel alloy coating |

| Symbols for steel products indicating special requirements | |

|---|---|

| Symbol | Meaning |

| +CH | core hardenability |

| +H | hardenability |

| +Z15 | through thickness property; minimum reduction of area = 15 % |

| +Z25 | through thickness property; minimum reduction of area = 25 % |

| +Z35 | through thickness property; minimum reduction of area = 35 % |