Q460 Steel Chemical Composition, Specifications, Properties & Equivalent

Q460 Steel Introduction

Q460 steel is a Chinese steel grade of Low Alloy High Strength Structural Steel, Yield Strength is 460 MPa, data is tested with 16mm diameter steel bars or steel plates, tensile strength is 550-720 Mpa, test with steel bar Ø≤40mm.For Q460 steel equivalent, chemical composition and mechanical properties, please see the tables below.

Properties and Applications

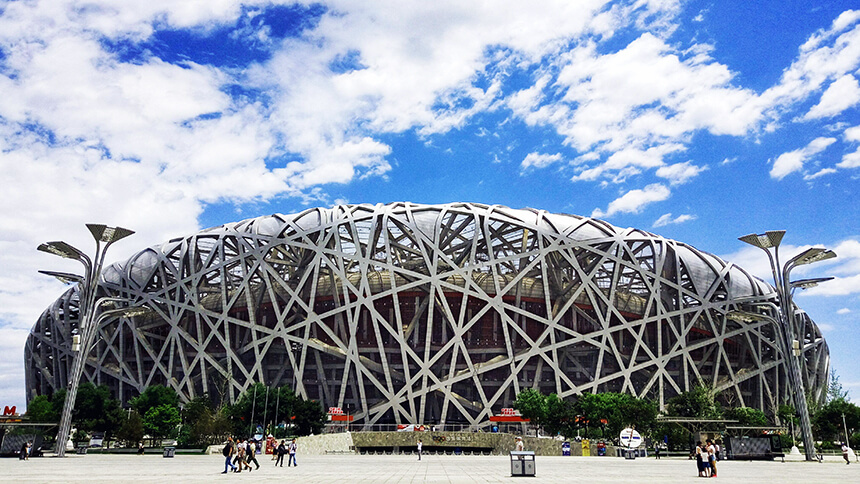

Q460 steel has much higher strength and has high comprehensive mechanical properties in normalizing, normalizing plus tempering, or quenching plus tempering, all of which are deoxidized with aluminum. It is used for large-scale engineering structures and lightweight structures that require high strength and large loads.

Datasheet & Specification

The following tables show Q460 alloy steel datasheet and specification, such as chemical composition, properties and equivalent grades, etc.

Table-1, Q460 Steel Chemical Composition

| Chemical Composition (GB/T 1591 – 2008) | ||||||||||||||||

| Steel Grade | Quality Grade | C % (≤) | Si (≤) | Mn (≤) | P (≤) | S (≤) | Nb (≤) | V (≤) | Ti (≤) | Cr (≤) | Ni (≤) | Cu (≤) | N (≤) | Mo (≤) | B (≤) | Als (≥) |

| Q460 | Q460C | 0.20 | 0.06 | 1.80 | 0.030 | 0.030 | 0.11 | 0.20 | 0.20 | 0.30 | 0.80 | 0.55 | 0.015 | 0.20 | 0.004 | 0.015 |

| Q460D | 0.030 | 0.025 | ||||||||||||||

| Q460E | 0.025 | 0.020 | ||||||||||||||

| Chemical Composition (GB/T 1591 – 2018) | ||||||||||||||

| Steel Grade | C % (≤) | Si (≤) | Mn (≤) | P (≤) | S (≤) | Nb (≤) | V (≤) | Ti (≤) | Cr (≤) | Ni (≤) | Cu (≤) | Mo (≤) | N (≤) | B (≤) |

| Q460C | 0.20 | 0.55 | 1.80 | 0.030 | 0.030 | 0.05 | 0.13 | 0.05 | 0.30 | 0.80 | 0.40 | 0.20 | 0.015 | 0.004 |

Table-2, Carbon Equivalent Value (CEV)

Delivered in hot rolled state (based on smelting analysis)

| CEV (Mass fraction ≤%); Nominal thickness or diameter Ø | ||||||

| Steel Grade | Quality Grade | ≤ 30 | 30 < Ø ≤ 63 | 63 < Ø ≤ 150 | 150 < Ø ≤ 250 | 250 < Ø ≤ 400 |

| Q420 | Q420C | 0.47 (CEV) | 0.49 | 0.49 | – | – |

Table-3, Q460 Mechanical Properties (Hot rolled)

| Thickness or Dia. (Ø) mm; Yield Strength (≥N/mm2) | ||||||||||

| Steel Grade | Quality | Ø≤16 | 16< Ø ≤40 | 40 < Ø ≤63 | 63 < Ø ≤ 80 | 80 < Ø ≤ 100 | 100 < Ø ≤ 150 | 150 < Ø ≤ 200 | 200 < Ø ≤ 250 | 250 < Ø ≤ 400 |

| Q460 | Q460C | 460 | 450 | 430 | 410 | 410 | 390 | – | – | – |

| Dia. (Ø) mm; Tensile Strength (N/mm2) | |||||

| Steel Grade | Quality Level | Ø≤100 | 100 < Ø ≤ 150 | 150 < Ø ≤ 250 | 250 < Ø ≤ 400 |

| Q460 | Q460C | 520 – 720 | 530 – 700 | – | – |

Table-4, Elongation

| Dia. (Ø) mm; Elongation (%) | |||||||

| Steel Grade | Sample direction | Ø≤40 | 40 < Ø ≤ 63 | 63 < Ø ≤ 100 | 100 < Ø ≤ 150 | 150 < Ø ≤ 200 | 250 < Ø ≤ 400 |

| Q460 | Horizontal | 20 | 19 | 19 | 18 | – | – |

| Vertical | 21 | 20 | 20 | 19 | – | – | |

Equivalent Grades

Q460 steel equivalent to US ASTM, European EN, German DIN EN, Japanese JIS, France NF EN, British BS EN and ISO standard (For reference purposes only)

| Q460 Equivalent | |||||||||||||

| China | US | German | Japan | France | UK | ISO | |||||||

| Grade | Standard | Grade | Standard | Grade | Standard | Grade | Standard | Grade | Standard | Grade | Standard | Grade | |

| Q460C | ASTM A572M | Gr.65 | DIN EN 10113-2, DIN EN10113-3 | S460NL, S460ML | JIS G3106, JIS G3114 | SM570, SMA570W, SMA570P | NF EN 10113-2, NF EN10113-3 | S460NL, S460ML | BS EN 10113-2, BS EN10113-3 | S460NL, S460ML | ISO 4950-2, ISO 4950-3 | E460CC, E460DD | |

| Q460D | ASTM A572M | Gr.65 | DIN EN 10113-2, DIN EN10113-3 | S460NL, S460ML | JIS G3106, JIS G3114 | SM570, SMA570W, SMA570P | NF EN 10113-2, NF EN 10113-3 | S460NL, S460ML | BS EN 10113-2, BS EN10113-3 | S460NL, S460ML | ISO 4950-2, ISO 4950-3 | E460DD, E460E | |

| Q460E | ASTM A572M | Gr.65 | DIN EN 10113-2, DIN EN10113-3 | S460NL, S460ML | JIS G3106, JIS G3114 | SM570, SMA570W, SMA570P | NF EN 10113-2, NF EN10113-3 | S460NL, S460ML | BS EN 10113-2, BS EN10113-3 | S460NL, S460ML | ISO 4950-2, ISO 4950-3 | E460E, E460E | |