DIN EN 1.2842 Steel 90MnCrV8 Material

DIN EN 1.2842 steel (90MnCrV8) is a European standard cold work tool steel and one of the most widely used tool steels, with high dimensional stability and edge retention and good machinability. Its properties and applications are basically the same as the material 1.2510 (100MnCrW4). In terms of its performance, DIN 1.2842 tool steel is comparable to the material 1.2510. Steel 1.2510 contains tungsten (W) element, which makes it have higher wear resistance and tempering resistance. DIN 1.2842 steel is suitable for cutting and punching tools, little shear blades, thread cutting rings and jaws, reamers, measuring tools, plastic and rubber molds.

Datasheet and Specifications

The following tables show 1.2842 steel datasheet and specification including chemical composition, physical properties and mechanical properties, heat treatment, etc.

Chemical Composition

1.2842 steel chemical composition is listed in the following table based on cast analysis.

| Chemical Composition (cast analysis), % | |||||||||

| Country (Region) | Standard | Steel Grade (Steel Number) | C | Si | Mn | P, ≤ | S, ≤ | Cr | V |

| European Union | EN ISO 4957 | 90MnCrV8 (1.2842) | 0,85-0,95 | 0,10-0,40 | 1,80-2,20 | 0,030 | 0,030 | 0,20-0,50 | 0,05-0,20 |

90MnCrV8 Steel Properties

The tables below list 90MnCrV8 steel properties, including physical and mechanical properties.

Physical Properties

DIN 1.2842 tool steel physical properties are given in the following lists, including density, thermal expansion, elastic modulus, thermal conductivity, specific heat capacity and electrical resistance.

Notes:

- 10-6·K-1 = 10-6/K

- 1 Ω·mm²/m = 1 μΩ·m

- 1 g/cm3 = 1 kg/dm3 = 1000 kg/m3

- 1 GPa = 1 kN/mm2

- 1 MPa = 1 N/mm2

| Physical Properties | |

| Density, g/cm3 | 7,85 |

| Electrical resistivity, μΩ·m | 0,35 (20 ℃) |

| Specific heat capacity, J/(kg·K) | 460 (20 ℃) |

| Thermal conductivity, (W/m·K) | 33 (20 ℃) |

| 32 (350 ℃) | |

| 31.3 (700 ℃) | |

| Modulus of elasticity, GPa | 210 |

| Mean coefficient of thermal expansion, (10-6/K) | 12.2 (20-100 ℃) |

| 13.2 (20-200 ℃) | |

| 13.8 (20-300 ℃) | |

| 14.3 (20-400 ℃) | |

| 14.7 (20-500 ℃) | |

| 15.0 (20-600 ℃) | |

| 15.3 (20-700 ℃) | |

Mechanical Properties

DIN 1.2842 90MnCrV8 mechanical properties are listed in the following tables.

| Mechanical Properties | ||||||

| Standard | Designation (Steel number) | Hardness (annealed), HBW, ≤ | Hardening test | |||

| Austenitizing temperature, °C | Quenching medium | Tempering temperature, °C | Hardness, HRC, ≥ | |||

| EN ISO 4957 | 90MnCrV8 (1.2842) | 229 | 790±10 | Oil | 180±10 | 60 |

Heat Treatment

- Hot forming temperature: 1050-850 °C.

- Soft annealing temperature: 690-720 °C.

- Stress-relief temperature: 600 – 650 °C, furnace cooling.

- Hardening temperature: 760-820 °C, quenching medium: oil, the Rockwell C hardness after quenching is 64 HRC.

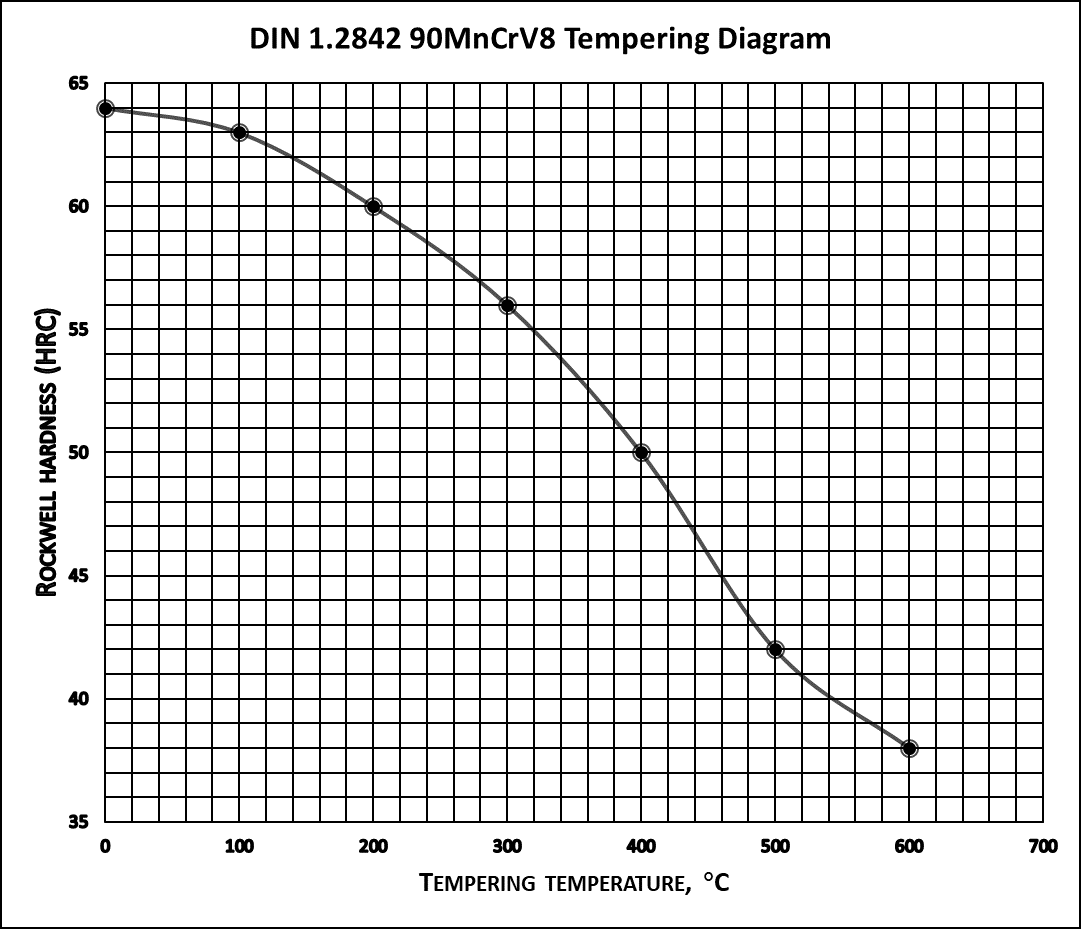

Tempering temperature and corresponding Rockwell hardness (HRC) are listed in the table below.

| Steel | Tempering temperature, °C | Rockwell hardness (HRC) |

| 90MnCrV8 (1.2842) | 100 | 63 |

| 200 | 60 | |

| 300 | 56 | |

| 400 | 50 | |

| 500 | 42 | |

| 600 | 38 |

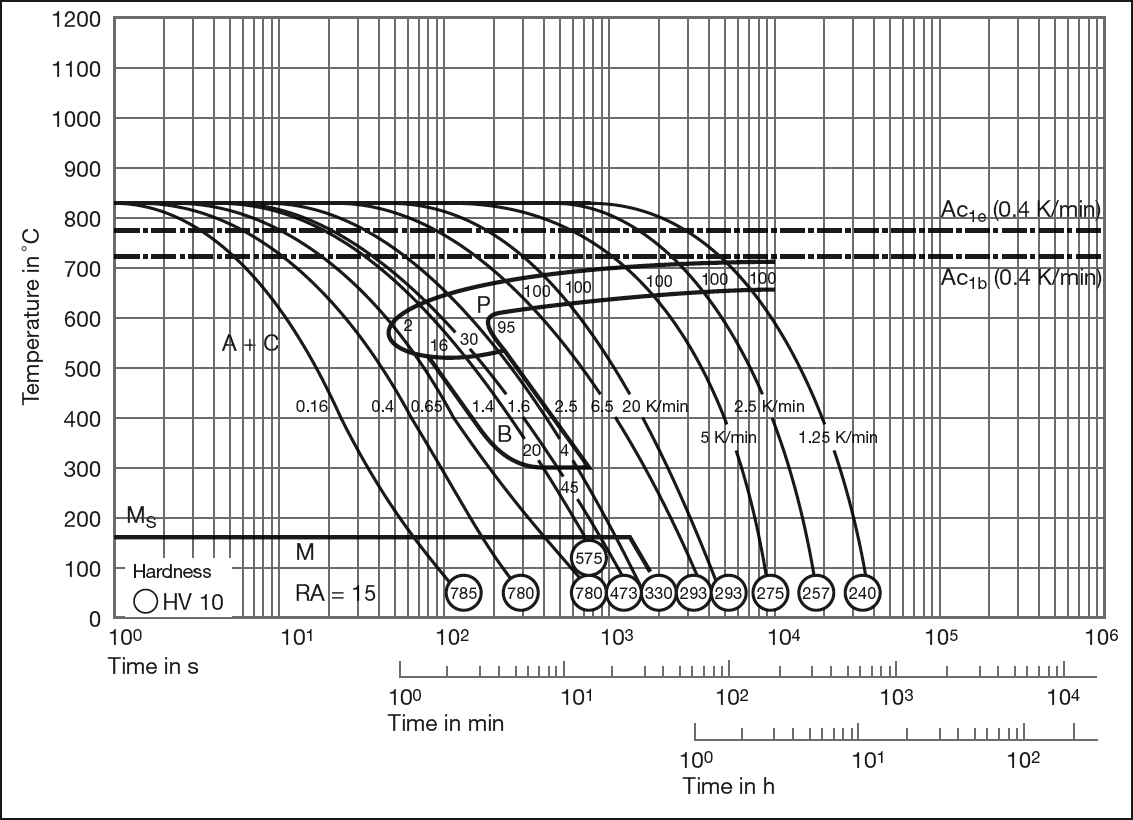

TTT Diagram

DIN 1.2842 tool steel 90MnCrV8 Time-temperature Transformation Diagram (TTT Diagram).

Applications

DIN 1.2842 90MnCrV8 steel is suitable for cutting and punching tools, little shear blades, thread cutting rings and jaws, reamers, measuring tools, sliders, rails, plastic and rubber molds.

Equivalent

DIN 1.2842 90MnCrV8 steel equivalent to AISI SAE, Japanese JIS and Chinese GB standard (for reference).

| 90MnCrV8 (1.2842) material equivalent | |||||||||

| European Union | US | ISO | China | Japan | |||||

| Standard | Steel Name (Material Number) | Standard | Grade (UNS) | Standard | Grade | Standard | Grade (UNS) | Standard | Grade |

| EN ISO 4957 | 90MnCrV8 (1.2842) | AISI; ASTM A681 | O2 (UNS T31502) | ISO 4957 | 90MnCrV8 | GB/T 1229 | 9Mn2V (T10029); 9CrWMn (T20299) | JIS G4404 | SKS3 |