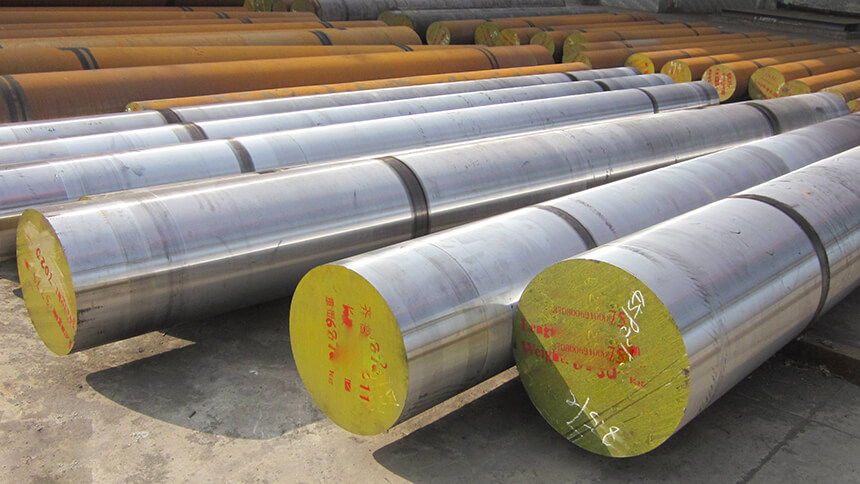

40CrNiMoA Steel

40CrNiMoA steel is a Chinese alloy steel, has high strength, toughness and good hardenability, and has anti-overheating stability, but has high white point sensitivity, temper brittleness and poor weldability. Preheating is required before welding, and stress relief treatment is required after welding.

Properties and Applications of 40CrNiMoA Alloy Steel

40CrNiMoA steel is used after quenching and tempering, and is used to manufacture important parts requiring good plasticity, high strength and large size. For example, heavy-duty shafts in heavy-duty machines, steam turbine shafts with diameters greater than 250 mm, blades, transmissions, fasteners, crankshafts, gears, etc., can also be used for rotor shafts and blades operating at temperatures exceeding 400 °C.

40CrNiMo, 40CrNiMoA Steel Chemical Composition

| Chemical Composition (%) | |||||||||

| Steel Grade | C | Si | Mn | P | S | Cr | Ni | Mo | Cu |

| 40CrNiMo 40CrNiMoA | 0.37 to 0.44 | 0.17 to 0.37 | 0.50 to 0.80 | ≤ 0.020 to ≤ 0.030 | ≤ 0.010 to ≤ 0.030 | 0.60 to 0.90 | 1.25 to 1.65 | 0.15 to 0.25 | ≤ 0.25 to ≤ 0.30 |

40CrNiMoA Alloy Steel Mechanical Properties

- Yield strength: ≥ 835 MPa

- Tensile strength: ≥ 980 MPa

- Elongation: ≥12%

- Rate of reduction in area: ≥55%

- Impact absorbing energy: ≥ 78 J

- Material Brinell Hardness: ≤ 269 (Annealed or high temperature tempered steel rod)

- Sample size: 25mm

Heat treatment specification

- First quenching heating temperature: 850 °C (Quenchant– oil)

- Tempering heating temperature: 600 °C (Quenchant– water, oil)

40CrNiMoA steel equivalent to European Germany DIN EN, UK BS EN, France NF EN 10083-3, grade 39NiCrMo3