SAE AISI 12L14 Steel Material

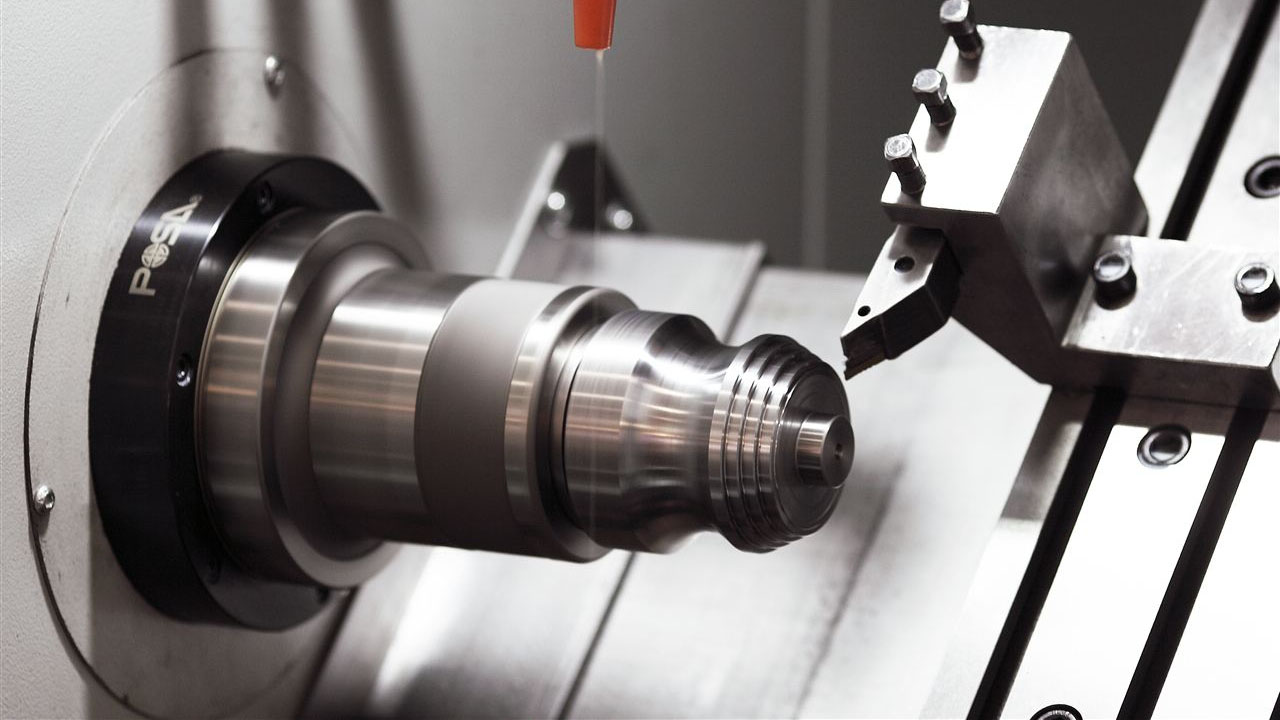

SAE AISI 12L14 steel is a resulfurized, rephosphorized and lead containing free-machining material, and is widely used in machinery, energy, metallurgy, aerospace and other fields.

The lower carbon content of 12L14 steel, especially the low melting point lead particles, ensures inherent lubrication of the steel during machining and embrittlement of the liquid metal at low machining speeds, thus avoiding the formation of Built-Up-Edge (BUE). In addition, phosphorus and sulfide inclusions form sources of stress concentration and discontinuities in the ferrite substrate, resulting in breakable chips. The sulfide-lubricated zone formed during machining reduces friction and tool wear, further improving its machinability. All these properties combine to make this material the most machinable of all common carbon and alloy steels. This machinability can be evaluated in terms of low cutting forces and good chip breaking characteristics.

Material 12L14 Steel Properties

12L14 material density is 7.87 g/cm³ (0.284 lb/in³); Tensile strength is 390 MPa (57 ksi) for hot rolled, 540 MPa (78 ksi) for cold rolled; Yield strength is 230 MPa (34 ksi) for hot rolled, 410 MPa (60 ksi) for cold rolled; Hardness is 121 HB (hot rolled), 163 HB (cold rolled).

Chemical Composition

| Chemical Composition | ||||||

| Standard | Steel | C, ≤ | Mn | P | S | Pb |

| ASTM A29/A29M | 12L14 | 0.15 | 0.85-1.15 | 0.04-0.09 | 0.26-0.35 | 0.15-0.35 |

12L14 Carbon Steel Mechanical Properties

| Carbon Steel | Type of Processing | Tensile strength, MPa (ksi), ≥ | Yield strength, MPa (ksi), ≥ | Elongation % ≥ | Reduction in area, % | Hardness, HB | Average machinability rating, % |

| 12L14 | Hot rolled | 390 (57) | 230 (34) | 22 | 45 | 121 | |

| Cold drawn | 540 (78) | 410 (60) | 10 | 35 | 163 | 170 |

Based on cold drawn 1212 carbon steel machinability rating = 100%.

Miscellaneous Material Properties

| AISI SAE 12L14 Steel Properties | Metric | Imperial |

| Density | 7.87 g/cm3 | 0.284 lb/in3 |

| Specific heat capacity | 472 J/kg·K | 0.113 Btu/lb ·°F |

| Electrical resistivity | 0.174 μΩ·m | 6.85 μΩ·in |

| Elastic modulus (Modulus of Elasticity) | 200 GPa | 29 x 106 psi |

| Shear Modulus | 80 GPa | 11.6 x 106 psi |

| Coefficient of thermal expansion (CTE) | 11.5×10-6/K at 20 °C | 6.39 μin./in.·°F at 68 °F |

| 12.2×10-6/K at 0-300 °C | 6.78 μin./in.·°F at 32-572 °F | |

| 13.9×10-6/K at 0-500 °C | 7.72 μin./in.·°F at 32-1000 °F | |

| Poissons Ratio | 0.29 | 0.29 |

SAE AISI 12L14 Steel Equivalent Material

SAE AISI 12L14 carbon steel equivalent material is listed in the table below, including US ASTM SAE, AISI; ISO, Japanese JIS, Chinese GB and European EN standard, etc.

| AISI 12L14 Steel Equivalent Material | |||||||||||||||||||

| US | European | ISO | German | Japan | China | Australia | India | Rusia | Korea | ||||||||||

| Standard | Steel Grade | Standard | Steel Name (Material Number) | Standard | ISO Designation | Standard | Steel Name (Material Number) | Standard | Steel Grade | Standard | Steel Grade | Standard | Grade | Standard | Grade | Standard | Grade | Standard | Grade |

| AISI, SAE; ASTM A29/A29M | 12L14 | EN ISO 683-4 :2018 | 10SPb20 (1.0722) | ISO 683-4:2018 | 10SPb20 | DIN EN 10087 (Withdrawn) | 10SPb20 (1.0722) | JIS G4804 | SUM24L | GB/T 8731 | Y12Pb | ||||||||

Note: DIN EN 10087 has been replaced by DIN EN ISO 683-4.