EN 1.0503 Material C45 Steel

EN 10083-2 C45 steel (EN 1.0503) is a high strength medium carbon quality steel. Due to poor hardenability, C45 material is generally used in a normalized condition, and when the mechanical properties are required to be high, the quenching and tempering treatment is adopted. The cold deformation plasticity is medium, and the machinability of annealing and normalizing is better than that of quenching and tempering.

C45 Steel Properties and Specifications

The table below gives the C45 steel properties and specifications including chemical composition, mechanical properties and heat treatment.

Chemical Composition

Datasheet 1, The following data sheet lists the C45 chemical composition based on casting analysis.

| Chemical Composition, % | ||||||||||

| Standard | Steel name (Steel number) | C | Si, ≤ | Mn | P, ≤ | S, ≤ | Cr, ≤ | Ni, ≤ | Mo, ≤ | Cr+Mo+Ni, ≤ |

| EN 10083-2 | C45 (1.0503) | 0.42-0.50 | 0.40 | 0.50-0.80 | 0.045 | 0.045 | 0.40 | 0.40 | 0.10 | 0.63 |

Mechanical Properties

The following table gives the C45 steel mechanical properties such as tensile strength, yield strength and hardness in the quenched and tempered, and normalized conditions.

Yield Strength

Datasheet 2, Yield strength in different diameter and conditions.

| Yield strength (MPa) | |||

| Steel (Steel number) | MPa, ≥ | Diameter (d), Thickness (t) in mm | Conditions |

| C45 (1.0503) | 490 | d ≤ 16 t ≤ 8 | Quenched and tempered (for the ruling section) |

| 430 | 16 < d ≤ 40 8 < t ≤ 20 | ||

| 370 | 40 < d ≤ 100 20 < t ≤ 60 | ||

| 340 | d, t ≤ 16 | Normalized (for products) | |

| 305 | 16 <d, t ≤ 100 | ||

| 275 | 100 <d, t ≤ 250 | ||

Tensile strength

Datasheet 3, Tensile strength in different diameter and conditions.

| Tensile strength (MPa) | |||

| Steel (Steel number) | Mpa | Diameter (d), Thickness (t) in mm | Conditions |

| C45 (1.0503) | 700-850 | d ≤ 16 t ≤ 8 | Quenched and tempered (for the ruling section) |

| 650- 800 | 16 < d ≤ 40 8 < t ≤ 20 | ||

| 630-780 | 40 < d ≤ 100 20 < t ≤ 60 | ||

| ≥ 620 | d, t ≤ 16 | Normalized (for products) | |

| ≥ 580 | 16 <d, t ≤ 100 | ||

| ≥ 560 | 100 <d, t ≤ 250 | ||

Elongation

Datasheet 4, Minimum percentage elongation after fracture.

| Elongation | |||

| Steel (Steel number) | ≥, % | Diameter (d), Thickness (t) in mm | Conditions |

| C45 (1.0503) | 14 | d ≤ 16 t ≤ 8 | Quenched and tempered (for the ruling section) |

| 16 | 16 < d ≤ 40 8 < t ≤ 20 | ||

| 17 | 40 < d ≤ 100 20 < t ≤ 60 | ||

| 14 | d, t ≤ 16 | Normalized (for products) | |

| 16 | 16 <d, t ≤ 100 | ||

| 16 | 100 <d, t ≤ 250 | ||

Reduction

Datasheet 5, Minimum percentage reduction in cross section on fracture in the quenched and tempered condition.

| Reduction in cross section (≥, %); Diameter (d), Thickness (t) in mm | |||

| Steel (Steel number) | d ≤ 16 t ≤ 8 | 16 < d ≤ 40 8 < t ≤ 20 | 40 < d ≤ 100 20 < t ≤ 60 |

| C45 (1.0503) | 35 | 40 | 45 |

Hardness

Datasheet 6, Products in the “treated to improve shearability” or “soft annealed” condition

| Hardness in different conditions | |||

| Standard | Steel name (Steel number) | (HBW) | Condition |

| EN 10083-2 | C45 (1.0503) | 255 | Treated to improve shearability |

| 207 | soft annealed | ||

Welding

Since material 1.0503 has a medium carbon content, it needs to preheat before welding, and the C45 material preheating temperature is 150 to 250 °C.

After welding, it’s better subjected to stress relief immediately, especially for large thickness weldments, the tempering temperature for stress relief is 550-660 °C.

Heat Treatment for Guidance

The heat treatment for C45 steel is mainly include quenching, tempering, normalizing and austenitizing, etc.

Quenching

The quenching temperature is 820-860 ℃, quenching agent is water (temperatures at the lower end of the range) or oil (upper end of temperatures). Guidance for austenitizing period is at least 30 min.

Tempering

The guidance for tempering temperature is 550-660 ℃, tempering period is at least 60 min.

Normalizing

The guidance for normalizing temperature is 840-900 ℃.

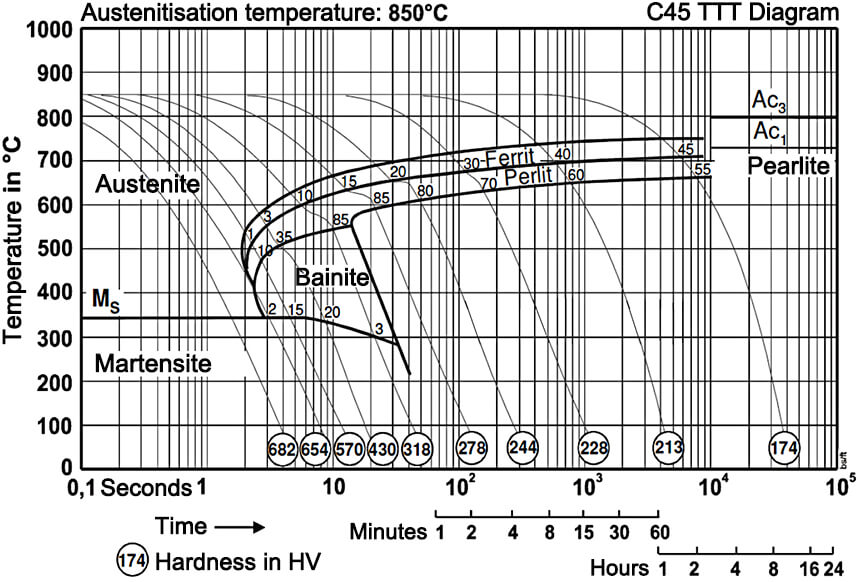

Isothermal Transformation Diagram

The image below shows C45 steel Isothermal Transformation Diagram (also known as Time Temperature Transformation, TTT) for reference.

Application

Material C45 (1.0503) is used to manufacture parts with high strength requirements, such as gears, shafts, piston pins, etc., and parts that are not very stressed, such as machined parts, forgings, stampings, bolts, nuts, and pipe joints.

C45 Material Equivalent Steel Grades

Datasheet 7, European standard (including Germany DIN, British BSI, French NF and other EU member state standards) C45 steel equivalent to Chinese GB standards, US ASTM AISI and SAE, Japanese JIS standards and ISO standards, etc.

| C45 steel equivalent material | ||||||||||

| European Union | Chinese | US | Japanese | ISO | ||||||

| Standard | Grade (Steel number) | Standard | Grade | Standard | Grade | Standard | Grade | Standard | Grade | |

| EN 10083-2 | C45 (1.0503) | GB/T 699 | 45 steel | AISI SAE, ASTM A29/A29M | 1045 steel | JIS G4051 | S45C | C45E4 | ||